High-voltage on the high seas

High-voltage and the ocean – how do these two things go together? Well, let’s imagine we are taking a boat out to the sea to enjoy nature. Around us is the vastness of the ocean, just the force of nature and relaxation. This romantic image is, however, destroyed with conventional boat drives because of the annoying smell of diesel, loud motor noises and harmful oil pollution. Do alternatives exist?

For a long time there was no environmentally friendly solution. What has become clear in the meanwhile though is that the boat industry must make its contribution to climate protection. The challenge is to reduce the environmental burden and at the same time raise the travelling comfort of taking a boat ride to a new level. Which is exactly where high voltage come into play.

The boat industry is developing more and more alternative drives. Omega Grey is a young company from Darmstadt which is seizing the opportunity arising from this transformation. The team pursues the goal of making the boat industry more sustainable and digital using an electric drive system with high-voltage technology. As a result unpleasant and disturbing odours, noise and vibrations are a thing of the past. The Omega Grey team describes the advantages of electric mobility in the boat industry and how the VadoTech training centre is helping with regard to the safety of the electric high-voltage systems in this blog post.

E-boats have motors that are environmentally friendly and save resources. Omega Grey has therefore developed a reliable drive system for boats as well as yachts. The desire of boat owners for an outstanding travelling experience with smart technology is realised with this system.

To ensure sustainable and intelligent mobility the Omega Grey team does without fossil fuels and relies on electric drives on the water. What is decisive apart from sustainability is the system’s degree of digitisation: The specially developed control unit links the individual components of the drive system such as the battery and motor into an entire system. This can be monitored at any time remotely. The energy flow on the boat can be controlled smartly through this link. Also allowing the remaining reach to be predicted reliably.

Since conditions on the sea are challenging, the components have to fulfil certain safety standards. With 20 years of experience in the automotive industry, Omega Grey designs the system on the basis of automotive standards. High waterproofness, durability and vibration resistance are critical factors for a reliable drive system. But what does the energy supply look like in practice? The lithium-ion batteries are charged via the shore-side power connection while in port. On the water the solar panels additionally supply the boat with sustainable energy. This even enables an autonomous travelling experience. This independence is also reflected in route planning not being restricted. More and more cities, such as Amsterdam, and protected areas, such as fjords in Norway, are imposing bans on combustion engines. Electric boats are excluded from such bans.

After an in-depth test phase of the high-voltage systems and all its components, the drive system from Omega Grey was installed into an all-electric 55-foot catamaran (shown in the preceding section) for the first time in November 2021. Shortly afterwards, in February 2022, the boat was put into operation.

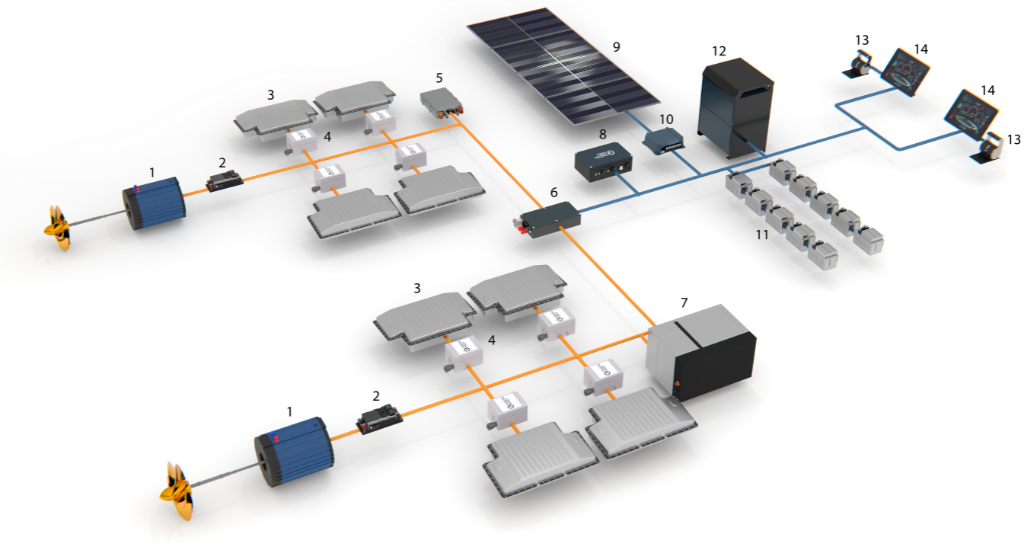

The two installed 100 kW electric motors are driven by eight Mercedes-Benz Energy batteries having a total of 110 kWh. With 10 kWh(p) of solar energy the e-boat can be driven or operated solely with solar energy in optimal conditions. The special feature of the electric catamaran is that it consists of a high-voltage and a low-voltage system. As the following figure shows, the motors are connected with 400 volts to the high-voltage system. The on-board supply, such as the fridge and the air conditioning, are connected with 48 volts to the low-voltage system. The DC/DC converter, in the meantime, ensures the conversion and connection of the two subsystems.

1.High-performance electric motor, 2.Motor controller, 3.HV lithium-ion battery incl. BMS, 4.OG Convert, Module (control unit), 5.Charger (shore-side power), 6.Bi-directional DC/DC converter, 7.Range extender (e.g. diesel generator), 8.OG Connect Module, 9.Solar panels, 10.Solar controller (MPPT), 11.LV lithium-ion battery, 12.DC-AC converter, 13.Drive lever, 14.On-board display

The lithium-ion batteries can be scaled up to an overall capacity of 420 kWh. For additional safety the integrated battery management system (BMS) monitors the batteries around the clock and protects against overheating and excessive discharging. This ensures that the batteries fulfil the highest safety and quality standards such as longevity and waterproofness.

Christian Ophoff, who together with Stefan Strauß, leads Omega Grey, took part in 2020 in VadoTech’s training “AuS - Working under voltage”. The training fully qualifies graduates to work with high voltage. Apart from theory and the legal basics, it was especially the practical exercises which lead to informative experience and an enormous gain in knowledge.

Since the first high-voltage training, the VadoTech Training Centre is the ideal address for Christian to visit further advanced training courses. VadoTech thus also accompanies the growth of Omega Grey by offering further training to become a qualified and recognised responsible electrician. By successfully completing this training, Christian can in the future instruct his employees on how to work with high-voltage systems in electric boats and thus ensure safe work under high voltage at all times.

Christian reports: “The training course has taught me the basics, theoretically as well as practically, to successfully realize my work with Omega Grey. It has helped me in becoming aware once more of the dangers of electricity.” Max Pawolek, VadoTech’s trainer, provided the High-voltage training in a lively manner with discussion sessions and clear and vivid practical examples.

Omega Grey uses the knowledge gained from the high-voltage training for its electric drive systems. These are crucial in particular during safety-critical situations such as the test phase and while commissioning the electric boats. Since special caution is required here, the system is first tested extensively before the high-voltage batteries are connected. After successful measurements and test phases the system is activated and maintained and serviced once a year.

Thanks to VadoTech’s comprehensive training offer, Omega Grey can develop a safe drive system for electric boats and thus pave the way for sustainable mobility on the water.

We’re here to help! You can reach out to us by phone at +49 30 327 644 13 or email us at training@vadotech.com. Our team is happy to assist you with any questions.

Get in touch

"*" indicates required fields

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information